- Home

- Resin

- Tackifier Resins

- Eastman™ Tackifier Resins (Hydrocarbon resin, HCR)

Eastman™ Tackifier Resins (Hydrocarbon resin, HCR)

Industry Categories

Functional

Product tags

Latest Products

Your most trustworthy partner

- Home

- Resin

- Tackifier Resins

- Eastman™ Tackifier Resins (Hydrocarbon resin, HCR)

Eastman™ Tackifier Resins (Hydrocarbon resin, HCR)

Last updated:

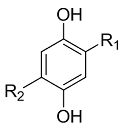

Eastman™ Tackifier Resins (Hydrocarbon resin, HCR), also known as tackifier resins, are byproducts of petroleum cracking. They are generally categorized into four types: C5 aliphatic, C9 aromatic, DCPD (dicyclopentadiene, cycloaliphatic), and pure monomers (e.g., poly SM, AMS, etc.). Because their molecular composition consists of carbon and hydrogen compounds, they are also referred to as hydrocarbon resins.

They have low acid values, good compatibility, resistance to water, ethanol, and chemicals. They exhibit chemical stability in both acidic and alkaline environments and have the characteristics of regulating viscosity and good heat stability. They are typically not used alone but in combination with other resins as promoters, modifiers, or modifiers.

Petroleum resins are classified into various types based on raw materials and processing, including aliphatic resins (C5), cycloaliphatic resins (DCPD), aromatic resins (C9), aliphatic/aromatic copolymer resins (C5/C9), hydrogenated petroleum resins, C5 hydrogenated petroleum resins, and C9 hydrogenated petroleum resins.

Remark:

• MMAP is a measurement of aromatic solubility and determines the aliphatic/aromatic character of the resin. The lower the MMAP value, the more aromatic the resin.

• DACP determines the polarity of the resin due to the highly polar nature of the solvent system. Since specific adhesion is related to the polarity of a resin,the DACP cloud point can be used as a specific adhesion indicator. The lower the DACP value, the better the specific adhesion of a resin.

C5 Aliphatic Resin

| C5Resin | Softening Point (℃) | Gardner | MMAP Cloud Point | MMAP Cloud Point |

| Piccotac1020 | 5 | 3 | 92 | 43 |

| Piccotac1095 | 94 | 3 | 94 | 52 |

| Piccotac1098 | 100 | 3 | 94 | 57 |

| Piccotac1100 | 100 | 3 | 96 | 62 |

| Piccotac1115 | 110 | 3 | 99 | 69 |

| Piccotac9105 | 105 | 2 | 92 | 60 |

| Piccotac9595 | 94 | 3 | 88 | 47 |

| Piccotac8595 | 95 | 3 | 82 | 40 |

| Piccotac8095 | 95 | 3 | 76 | 38 |

| Piccotac7050 | 60 | 3 | 65 | 7 |

| Piccotac7050-N | 91 | 2 | 62 | 22 |

| Piccotac6095E | 98 | 7 | 35 | -10 |

C9 Aromatic Resin

| C9 Resin | Softening Point (℃) | Color |

MMAP Cloud Point | MMAP Cloud Point |

| Picco A10 | liquid | 9 | – | -24 |

| Picco A100 | 101 | 9 | – | <-40 |

| Picco A120 | 125 | 8 | 2 | <-40 |

| Picco A120PI | 120 | 6 | – | – |

| Picco A130 | 135 | 6 | – | – |

| Picco A140 | 142 | 8 | 3 | <-40 |

| Picco A140PI | 138 | 6 | – | – |

| Picco AR85 | 87 | 9 | 3 | <-40 |

| Picco AR100 | 100 | 8 | 4 | <-40 |

Hydrogenated C5(H2C5)

Hydrogenation will optimize product color and improve its stability against high temperatures, oxidation, and UV radiation.

| H2C5 Resin | Softening Point (℃) | Gardner | MMAP Cloud Point | MMAP Cloud Point |

| Eastotca C-100R | 100 | 1.5 | 78 | 56 |

| Eastotca C-100L | 100 | <1 | 81 | 57 |

| Eastotca C-100W | 100 | <1,4(YID) | 83 | 64 |

| Eastotca C-100XF | 100 | <1,2(YID) | 83 | 64 |

| Eastotca C-115R | 115 | 1.5 | 78 | 60 |

| Eastotca C-115L | 115 | <1 | 80 | 61 |

| Eastotca C-115W | 115 | <1 | 85 | 68 |

| Eastotca H-100R | 100 | 1.5 | 79 | 68 |

| Eastotca H-100L | 100 | <1 | 78 | 65 |

| Eastotca H-100W | 100 | <1 | 81 | 69 |

| Eastotca H-115R | 115 | 1.5 | 82 | 76 |

| Eastotca H-115L | 115 | <1 | 82 | 75 |

| Eastotca H-115W | 115 | <1 | 80 | 68 |

| Eastotca H-130R | 130 | 1.5 | 81 | 70 |

| Eastotca H-130L | 130 | <1 | 83 | 77 |

| Eastotca H-130W | 130 | <1 | 83 | 76 |

| Eastotca H-142R | 142 | 1.5 | 82 | 74 |

| Eastotca H-142W | 142 | <1 | 85 | 76 |

Hydrogenated C9(H2C9)

| H2C9 Resin | Softening Point (℃) | Gardner | MMAP Cloud Point | MMAP Cloud Point |

| Regalite™ R1010 | liquid | <1 | 82 | – |

| Regalite™ R1090 | 88 | +1.0 | 74 | 39 |

| Regalite™ R1100 | 100 | +0.8 | 78 | 45 |

| Regalite™ S1100 | 100 | <1 | 82 | 46 |

| Regalite™ R1125 | 129 | +1.0 | 86 | 56 |

| Regalite™ R9100 | 99 | +4.6 | 71 | 36 |

| Regalite™ C8010 | liquid | <1 | 76 | 29 |

| Regalite™ R7100 | 102 | <1 | 63 | 14 |

| Regalite™ R7125 | 122 | <1 | 72 | 35 |

| Regalite™ C6100 | 100 | <1 | 60 | 31 |

| Regalite™ C6100SD | 100 | <1 | 60 | 31 |

| Regalite™ C6100L | 100 | <1 | 55 | 23 |

| Regalite™ S5100 | 97 | <1 | 59 | 8 |

| Plastolyn™ R1140 | 140 | <1 | – | – |

Pure Monomer Resin (PMR)

Pure Monomer Resin is made from highly purified raw materials, with excellent color and precise control over product composition.

| Pure Monomer Resin | Softening Point (℃) | Color (YID) | MMAP Cloud Point | MMAP Cloud Point |

| Endex™ 155 | 153 | 5 | 16 | -23 |

| Endex™ 160 | 159 | 8 | 16 | -15 |

| Kristalex™ 1120 | 119 | 7 | 5 | -35 |

| Kristalex™ 3070 | 70 | 7 | 0 | <-50 |

| Kristalex™ 3085 | 85 | 4 | 1 | <-50 |

| Kristalex™ 3100 | 100 | 5 | 5 | <-50 |

| Kristalex™ 3100LV | 100 | 5 | 6 | -40 |

| Kristalex™ 3105SD | 105 | 8 | 4 | <-40 |

| Kristalex™ 5140SD | 140 | 7 | 10 | -40 |

| Kristalex™ 3115 | 115 | 10 | 3 | <-50 |

| Kristalex™ 3115LV | 120 | 10 | 5 | -40 |

| Kristalex™ 5140 | 139 | 4 | 9 | -48 |

| Kristalex™ 5140LV | 140 | 7 | 10 | -40 |

| Kristalex™ F85 | 86 | <1 | 1 | 445 |

| Kristalex™ F100 | 99 | <1 | 2 | 57 |

| Kristalex™ F226 | 117 | <1 | 2 | 80 |

| Plastolyn™ 240 | 121 | 11 | 8 | <-50 |

| Plastolyn™ 290 | 140 | 13 | 9 | -44 |

| Plastolyn™ 290LV | 140 | 7 | 8 | <-40 |

Hydrogenated Pure Monomer Resin (H2PMR)

| Pure Monomer Resin | Softening Point (℃) | Color (YID) | MMAP Cloud Point | MMAP Cloud Point |

| Regalrez™ 1018 | 19 | 6 | 64 | 14 |

| Regalrez™ 1094 | 95 | 2 | 84 | 59 |

| Regalrez™ 1126 | 124 | 2 | 92 | 76 |

| Regalrez™ 1137 | 141 | 2 | 109 | 79 |

| Regalrez™ 3102 | 102 | 3 | 24 | -15 |

| Regalrez™ 6108 | 108 | 3 | 53 | 25 |