Industry Categories

Functional

Product tags

Latest Products

Your most trustworthy partner

Last updated:

Tenite™ cellulosic plastics

Since Tenite™ cellulosics was first introduced in 1929, it has become a staple of the plastics industry. Tenite™ is a versatile, durable, and attractive cellulosic plastic. It has been used in consumer product applications from radios and telephones, to toothbrushes and toys.

Tenite™ cellulosic plastics are noted for their excellent balance of properties - toughness, hardness, strength, surface gloss, clarity, chemical resistance, and warmth to the touch. Tenite™ products are also easily molded, extruded, or fabricated and available in natural, clear, amber, and black.

In keeping with Eastman's tradition of environmental consciousness, Tenite™ cellulosics is made from 100% renewable softwood materials.

Tenite™ cellulosic plastics are noted for their excellent balance of properties - toughness, hardness, strength, surface gloss, clarity, and a warm feel. The mechanical properties if Tenite™ cellulosic plastics differ with plasticizer levels. Lower plasticizer content yields a harder surface, higher heat resistance, greater rigidity, higher tensile strength, and better dimensional stability. Higher plasticizer content increases impact strength.

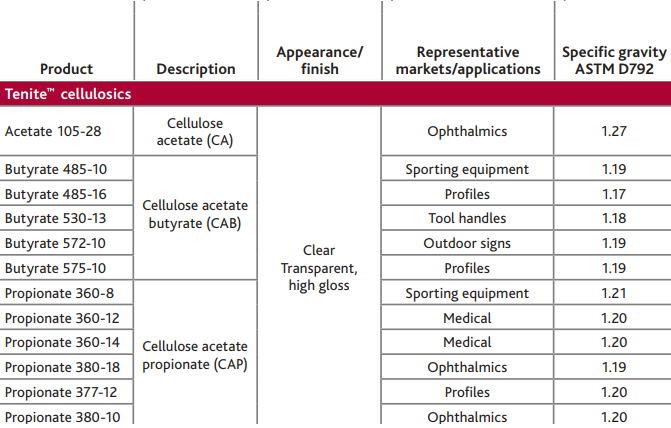

Tenite™ Acetate

Under certain formulations and processing techniques.

products with higher surface hardness than cellulose acetate butyrate or cellulose acetate propionate can be produced

Tenite™ Propionate

Applications requiring high hardness, high tensile strength, and high rigidity characteristics.

Tenite™ Butyrate Cellulose Acetate Series

Applications requiring weather resistance, dimensional stability, or softer end products.

Tenite™ Product Description:

Eyeglass lenses

Automotive and furniture decorations

Displays

Cosmetic containers

Moldings or tubing

Optical safety eyeglass frames