Industry Categories

Functional

Product tags

Non-flammable

Fast Drying

Low Dielectric Property

Low Water Solubility

Low Viscosity

Low Evaporation Rate

Low Surface Tension

Low Viscosity

Reduced Gloss

Excellent Dispersion

Plasticizer

Shine

Increased Abrasiveness

Excellent Conductivity

Coalescent

Anti-UV

Scratch Resistance

Antioxidants

Hydrolytic

Impact Resistance

Impact Modifier

Enhanced color

Increased color intensity

Improve Leveling

Effect pigment

Scale Control

Water Treatment

Detergent

Lubricating oil

Non-toxic and Environmentally Friendly

Slow Evaporation Rate

Weather Resistance

Lightfastness

Heat Resistance

High Temperature Resistance

Polymer Modifiers

Pigment

Transparency

Modeling Agent

Anti-hail

Anti Graffiti

Releasing Property

High Molecular Weight

High Stability

High Boiling Point

Latest Products

Your most trustworthy partner

Easchem Co., Ltd. provides professional and timely services, as well as the highest quality products, hence our cooperative clients are distributed throughout the Asia-Pacific region. We are your most reliable partner.

Last updated:

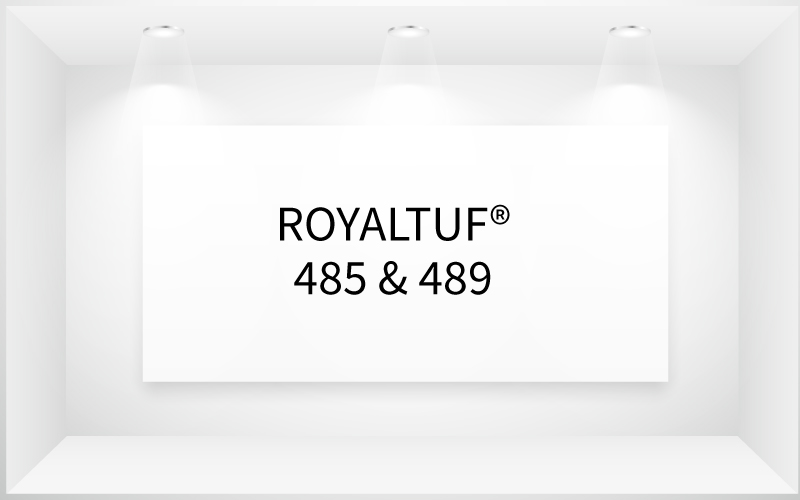

ROYALTUF® impact modifiers are widely used to toughen polyamides and provide excellent room temperature and low-temperature impact resistance.

| Polymer

Type |

Functional Groups | Functional group content | Melt Flow Index

ML(1 +4)@125°C |

MFR @265°C,

21.6kg g/10 min |

Physical Form | |

| ROYALTUF® 485 | Semi-crystalline EPDM | Maleic Anhydride (MA) | Medium | 30 | – | Granular |

| ROYALTUF® 489 | Non-crystalline EPDM | Maleic Anhydride (MA) | High | 30 | – | Granular |

| ROYALTUF® ESG 115B R-2 | Semi-crystalline EPDM | Acrylonitrile-Styrene (SAN) | Medium | – | – | Granular |

| ROYALTUF® 372P20 | Semi-crystalline EPDM | Acrylonitrile-Styrene (SAN) | Medium | – | 20 | Granular |

Facebook

Twitter

LINE

WeChat

WhatsApp