- Home

- Plastics

- Food Packaging

- Eastman™ Cellulose Acetate

Eastman™ Cellulose Acetate

Industry Categories

Functional

Product tags

Latest Products

Your most trustworthy partner

- Home

- Plastics

- Food Packaging

- Eastman™ Cellulose Acetate

Eastman™ Cellulose Acetate

Last updated:

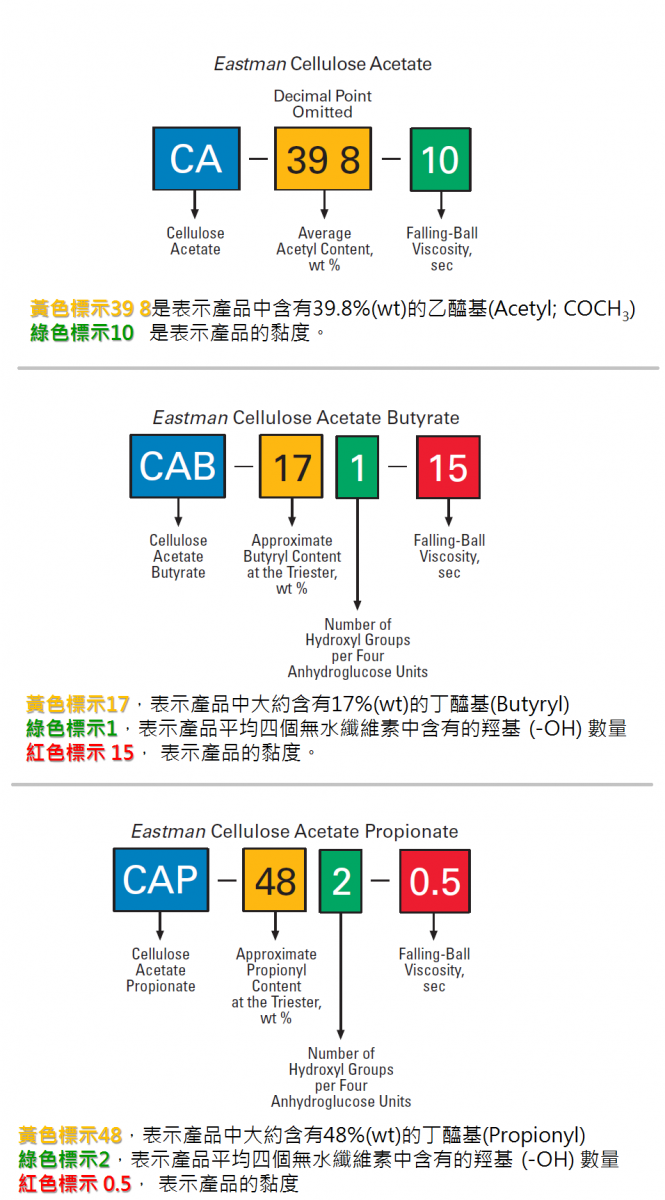

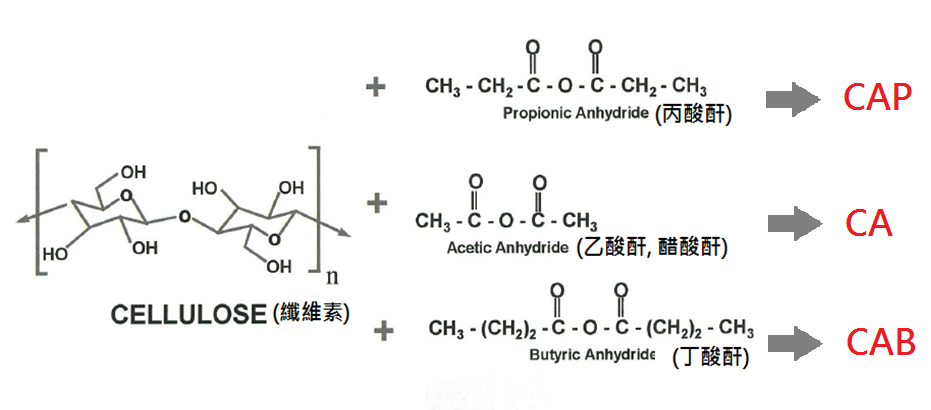

Eastman Cellulose Acetate (CAB, CAP and CA) is a green product made from sustainable and renewable resources for a wide range of applications. Cellulose acetate provides improvements in properties such as rheology control, drying time, appearance, orientation of metal aluminum powder, turbulence, flow and leveling, blocking resistance and printability.

Cellulose Esters Product List

Eastman™ Cellulose acetate (CA)

|

|

Viscositya |

Acetyl Content (wt %) |

OH (%) |

Melting Range (℃) |

Tg (℃) |

Density (Kg/L) |

MW (Wt/Vol) |

|

CA 394-60S |

60 |

39.5 |

4.0 |

240-260 |

180 |

132 |

60000 |

|

CA 398-3 |

3.00 |

39.8 |

3.5 |

230-250 |

180 |

1.31 |

30000 |

|

CA 436-80S |

80 |

43.6 |

0.82 |

269-300 |

– |

1.34 |

– |

Eastman™ Cellulose acetate propionate (CAP)

|

|

Viscositya |

Acetyl Content (wt %) |

OH (%) |

Melting Range (℃) |

Tg (℃) |

Density (Kg/L) |

MW (Wt/Vol) |

|

CAP 482-0.5 |

0.4 |

45 |

2.6 |

188-210 |

142 |

1.22 |

15000 |

|

CAP 482-20 |

20 |

48 |

1.8 |

188-210 |

147 |

1.22 |

75000 |

|

CAP 504-0.2 |

0.2 |

42.5 |

5.0 |

188-210 |

159 |

1.26 |

25000 |

Eastman™ Cellulose Acetate Butyrate (CAB)

|

|

Viscositya |

Butyryl content (wt %) |

OH (%) |

Melting Range (℃) |

Tg (℃) |

Density (Kg/L) |

MW (Wt/Vol) |

|

CAB 171-15 |

15 |

17 |

1.5 |

230-240 |

161 |

1.26 |

65000 |

|

CAB 321-0.1 |

0.1 |

32.5 |

1.3 |

165-175 |

127 |

1.20 |

12000 |

|

CAB 381-0.1 |

0.1 |

38.0 |

1.3 |

155-165 |

123 |

1.20 |

20000 |

|

CAB 381-0.5 |

0.5 |

38.0 |

1.3 |

155-165 |

130 |

1.20 |

30000 |

|

CAB 381-2 |

2 |

38.0 |

1.3 |

171-184 |

133 |

1.20 |

40000 |

|

CAB 381-20 |

20 |

37 |

1.8 |

195-205 |

141 |

1.20 |

70000 |

|

CAB 381-20 BP |

16.0 |

35.5 |

0.8 |

185-195 |

130 |

1.20 |

70000 |

|

CAB 500-5 |

1.9 |

51.0 |

1.0 |

165-175 |

96 |

1.18 |

57000 |

|

CAB 531-1 |

1.9 |

50.0 |

1.7 |

135-150 |

115 |

1.17 |

40000 |

|

CAB 551-0.01 |

0.01 |

52.0 |

1.5 |

127-142 |

85 |

1.16 |

16000 |

|

CAB 551-0.2 |

0.2 |

51.0 |

1.8 |

130-140 |

101 |

1.16 |

30000 |

|

CAB 553-0.4 |

0.3 |

46.0 |

4.8 |

150-160 |

136 |

1.20 |

20000 |

Cellulose Esters Applications/Uses:

|

Applications |

CA |

CAB |

CAP |

Benefits |

|

coatings for metal |

|

○ |

|

Improves intercoat adhesion and metallic flake control. Good resistance to salt spray . Reduces cratering and dry-to-touch time. Anti-yellowing. Control viscosity.Anti-back tack . |

|

Plastic Coatings |

|

○ |

|

Improves intercoat adhesion and metallic flake control .Anti-yellowing . Anti-back tack . Reduces cratering and dry-to-touch time. |

|

coatings for wood |

|

○ |

|

Improves intercoat adhesion and metallic flake control .Anti-yellowing . Anti-back tack . Reduces cratering and dry-to-touch time. |

|

Inks |

○ |

○ |

○ |

Metallic flake control . Anti-yellowing . Control viscosity . Anti-back tack. . Reduces cratering and dry-to-touch time. |

|

Release Films |

○ |

|

|

Good to release molding . Low odor . Gives high strength and good resistance to ultraviolet light, heat, oils, and greases. |

|

UV Coating Additive |

|

○ |

|

Anti Warp |

|

Leather Coatings |

|

○ |

|

Driers. Anti-yellowing . Control viscosity . Anti-back tack . Reduces cratering and dry-to-touch time. |

|

Food Packaging |

|

|

○ |

Low odor. Excellent solvent release. Can be use in painting ink |

|

Adhesion of textile |

|

○ |

|

Higher viscosity and increased toughness with excellent surface hardness . |

|

Vacuum Metalizing |

|

○ |

|

Smooth the surface. metallic flake control . Anti-yellowing |

|

Dispersed Pigments |

|

○ |

|

With excellent wetting characteristics |

|

Automotive Coatings |

|

○ |

|

Improves intercoat adhesion and metallic flake control .Anti-yellowing . Anti-back tack . Reduces cratering and dry-to-touch time. |