- Home

- Plastics

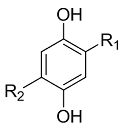

- Non-toxic and eco-friendly plasticizers

- Eastman TXIB™ Formulation Additive

Eastman TXIB™ Formulation Additive

Industry Categories

Functional

Product tags

Latest Products

Your most trustworthy partner

- Home

- Plastics

- Non-toxic and eco-friendly plasticizers

- Eastman TXIB™ Formulation Additive

Last updated:

Eastman TXIB™ Formulation

Additive is the lowest viscosity (9 cps) additive available to the flexible PVC industry. Eastman TXIB™ Formulation Additive is completely compatible with PVC in all proportions and is usually blended with general-purpose plasticizers such as DOP or DOTP. The unique low viscosity makes this material particularly suitable for PVC plastisols and often allows adding additional fillers to the plastisol, resulting in a cost savings.

Eastman TXIB™ Formulation Additive has efficiency generally equal to DOP, which makes substitution in a vinyl formulation very easy. It imparts a dry surface to the vinyl, excellent resistance to staining, and physical properties equivalent to DOP. Eastman TXIB™ Formulation Additive is also used in inks, coatings, urethane elastomers, and nail polish lacquers.

|

Physical Characteristics |

Values |

|

Molecular Weight |

286.4 |

|

density @20 °C |

0.942-0.948 |

|

Acidity (calculated as isobutyric acid) |

Maximum 0.05 wt% |

|

Surface Tension @25 °C |

27.56 dynes/cm |

|

Boiling point @ 760 mmHg |

281°C (537.8°F) |

|

Freezing point |

-70 °C (-94°F) |

|

Flash point (Cleveland Open Cup / COC). |

143°C (290°F) |

|

Auto-ignition temperature |

424°C (795°F) |

|

Evaporation rate @ 100°C |

0.674 (g/1000 cm2)/h |

|

Hydrolysis After 96 hours @99℃ |

0.003% |

|

Viscosity @ 25°C |

9 cP |

|

content |

Minimum 98.5 wt % |

|

color Pt-Co |

Maximum 10 |