- Home

- Building Materials

- External walls

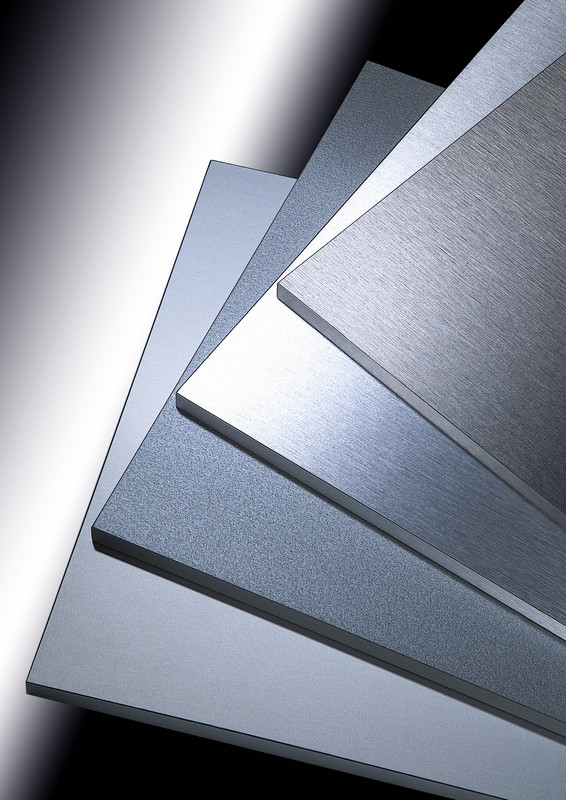

- FUNDERMAX Building Exterior M Look

FUNDERMAX Building Exterior M Look

Industry Categories

Functional

Product tags

Latest Products

Your most trustworthy partner

- Home

- Building Materials

- External walls

- FUNDERMAX Building Exterior M Look

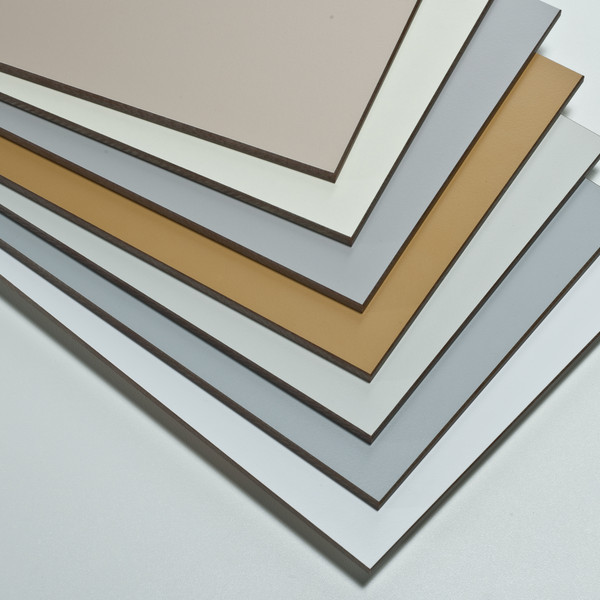

FUNDERMAX Building Exterior M Look

Last updated:

Heavy glass fiber primarily consists of minerals, is non-flammable, and has a highly weather-resistant decorative surface.

The most important attributes for the decorative surface are high scratch resistance, lightfastness, impact resistance, anti-graffiti properties, ease of cleaning, and hail resistance, tested according to EN438-2.

Structure:

The aluminum structure must meet national standards and be installed according to the manufacturer's specifications.

The aluminum base structure is primarily composed of vertical supports installed at angles on the wall.

Due to the material characteristics of m.look panels, fixed points and sliding points are needed for panel installation.

The dimensions of the metal substructure vary with temperature changes.

However, the dimensions of the m.look panels vary with changes in relative humidity.

These dimensional changes may be in opposite directions for the substructure and wall panel material.

Therefore, it is necessary to ensure sufficient expansion space when installing m.look panels.

Sliding Points:

The drilling diameter for m.look panels should be 8.5 millimeters.

The fastening at the top means that the holes must always be covered. Fasteners should be set up so that the panel can move.

Rivets must be present.

Use rivets to place them according to the centralized placement guidelines. The specified distance from the top to the panel surface for rivets (0.3 millimeters) allows parts to move in the drilled holes. The hole centers of the substructure must align with the holes on m.look panels.

Proper drilling guides should be used.

Panels should be fixed from the center outward. Alternatively, the sliding point is at the same height as the fixed point, and it can be made as a loose point with a groove

(height = 5.1 millimeters; width = 8.5 millimeters).

Fixed Points:

Fixed points are used to evenly distribute expansion and contraction (halving) movements. The drilling diameter for m.look panels should be 5.1 millimeters.

Fasteners:

Alu-Blind rivets with large painted heads.

Rivet body: Material - None. EN AW-5019

Rivet mandrel: Material - None. 1.4541

Pull-out strength of the rivet mandrel: 5.6 KN.

Drilling diameter on m.look panels: Sliding point: 8.5 millimeters, Fixed point: 5.1 millimeters.

Aluminum drilling diameter, substructure: 5.1 millimeters.

Rivets 5.0 x 16 K14, used for support bracket thickness 2.0≤t≤3.0 millimeters.

Rivets 5.0 x 18 K14, used for support bracket thickness 3.0.

Edge Spacing:

It is absolutely necessary to observe an edge distance of 30 millimeters to ensure stability and flatness. To accommodate size variations, the joints between panels must be 8±1mm (as shown in the upper figure).

Fastening Spacing:

The fixed distances should be selected in the middle, according to structural requirements (calculations) or, if not necessary, due to local building regulations, fixed distances from Table 2 to 7 for the peripheral areas are smaller, and the building ratio is smaller in the central area.