- Home

- Building Materials

- Processing Panels

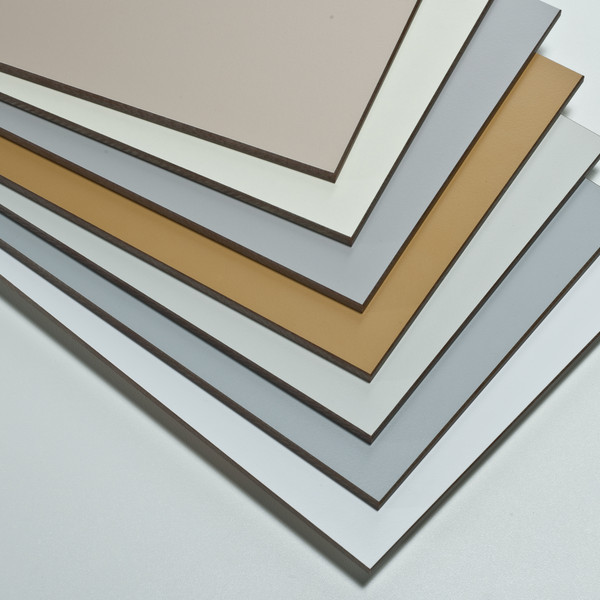

- FUNDERMAX Building Facades M Look General

FUNDERMAX Building Facades M Look General

Industry Categories

Functional

Product tags

Latest Products

Your most trustworthy partner

- Home

- Building Materials

- Processing Panels

- FUNDERMAX Building Facades M Look General

FUNDERMAX Building Facades M Look General

Last updated:

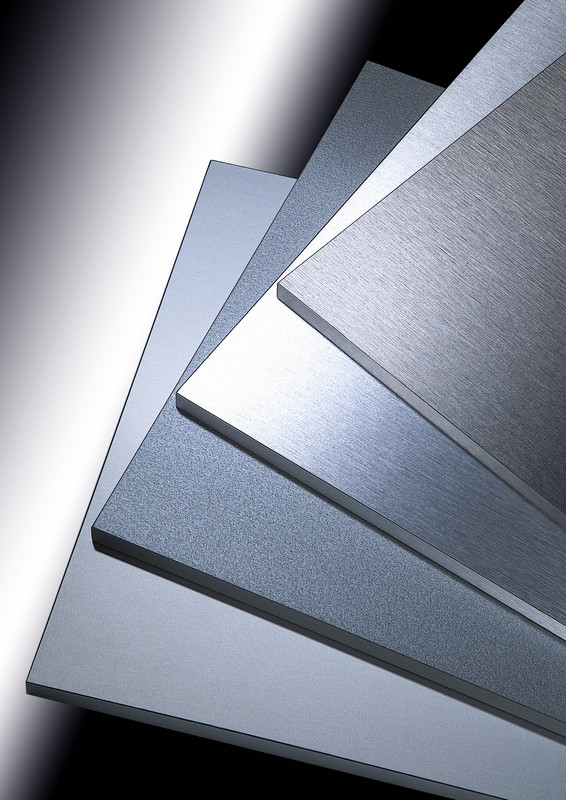

Heavy glass fiber primarily consists of minerals, is non-flammable, and has a highly weather-resistant decorative surface.

The most important attributes for the decorative surface are high scratch resistance, lightfastness, impact resistance, anti-graffiti properties, ease of cleaning, and hail resistance, tested according to EN438-2.

Surface NT:

Format: 3660 x 1630 millimeters

Tolerance: -0 / +10 mm

Panel dimensions are the production dimensions. It is recommended to cut off all edges.

Precision in dimensions, panel sides, and angles are necessary.

Depending on the cuts, the net weight decreases by approximately 10 millimeters.

Classification: A2-s1, d0 in accordance with EN13501-1, thickness 7 millimeters.

Panels are designed with double-sided decoration, with a tolerance of ±0.4 mm.

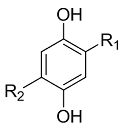

Decoration Layer:

Minerale core.

Decoration layer: 3660 millimeters x 1630 millimeters.

Material Characteristics: m.look panels contract when releasing moisture and expand when absorbing moisture.

When using m.look panels in construction, these potential size changes must be considered.

Dimensional changes of m.look: Panels typically shrink by approximately 30%, more in the length (longitudinal) than in the width (transverse) relative to standard panel dimensions.

Element length = a, element width = b, a or b (mm) = exp (limit).

Please note that the text contains some technical information and measurements related to the characteristics of m.look panels. If you have any specific questions or need further clarification, please feel free to ask.

M look Product Specifications:

Panel Dimensions Testing Method Tolerance

Values Unit

Length – 0 / +10 mm 3,660 mm

Width – 0 / +10 mm 1,630 mm

Thickness + 0.4,7 mm

Flatness EN 438-6 / 5.3 ≤5 mm/m

Type Testing Method Tolerance Values Unit

Decor based on current decorative range

Special Decoration Requirements:

Cutting length/width + 0.5 mm

Processing as per requirements (drilling, milling, CNC)

Surface texture NT

Substructure aluminum, steel

Wall anchor Fassadenniet Alu / Niro K14

Maximum spacing for fixing according to requirements: 800 mm

Structural standard for panel type

Joint width 8 ± 1 millimeters

Property Test Method Standard Values Units

Building material grade EN 13501-1, A2-s1, d0

Fire resistance EN ISO 1716 ≤ 3 ≤ 3 MJ/kg

Surface protection Weather protection,

including patent, dual-curing acrylic

polyurethane resin

Decorative layer lightfastness (standard) EN 438-2 / 29 ≥ 3 ≥ 3 gray scale

Decorative layer lightfastness (special) EN 438-2 / 29 ≥ 4 gray scale

Scratch resistance (surface hardness) EN 438-2 / 25 ≥ 3 degrees

Hail class VKF No. 11 HW 5

Bending strength EN ISO 178 ≥ 36 MPa

E-Module EN ISO 178 ≥ 7500 MPa

Weight 13.5 kg/m2

Density EN ISO 1183-1, 1.9 g/cm³

Thermal resistance EN 12667, 0.0327 m2K/W

Dimensional change EOTA wall ETAG 034 < 0.8 mm/m

Freeze/thaw cycle test EN 438-2 / 19

Passed thickness expansion after 24 hours EN 317 < 0.1%

Physical Property Test Methods, Standard Values, and Units:

As specified for other building materials (Austrian Standard No. 91401).

Formaldehyde Emission: EN717-1 ≤ 0.1 ≤ 0.02 ppm.

VOC Emissions (TVOC) AgBB: ≤ 10.0 mg/m³.

M Look Features and Benefits:

(1) Rain Protection:

VHF complies with Pressure Standard III, in accordance with DIN 4108-3, and protects against rainwater penetration.

It has a low percentage of water absorption when exposed to rain, and any water not evaporated quickly drains away from the surface of the facade through the ventilated space and insulation layers (weather protection).

(2) Insulation:

Non-bearing ventilated curtain wall (VHF) systems can be designed to meet individual requirements for different energy calculations.

Therefore, any required insulation thickness can be used. This refers to typical insulation values for low-energy, passive-energy, or functional buildings that comply with current regulations, making energy efficiency easy to achieve. Insulation maximizes heat retention based on energy demand.

In the summer, when temperatures are high, the building's interior is regulated by reducing the energy needed for heating, thus minimizing carbon dioxide emissions from heating systems.

(3) Noise Prevention:

Depending on the thickness of the insulation layer, the size of panels, and the ratio of openings, noise protection can be as high as 14 dB.

(4) Prevention of Condensation:

In non-bearing structures, ventilated curtain walls reduce the resistance to steam diffusion from the building's interior to the outside. By removing moisture from the building's exterior to the ventilated space, lasting insulation function can be ensured, contributing significantly to creating a pleasant and healthy indoor climate.

(5) Economic:

Economic aspects can also be found in the requirements for sustainable development.

Construction: The use of long-life materials and long maintenance cycles is a key point.

Cost certainty: Non-bearing ventilated curtain walls achieve precise cost planning, even for renovations.

(6) General Building Information:

During construction and installation, ensure that materials are not exposed to water or standing water.

Panels must always be kept dry. m.look panels may exhibit flatness deviations. These should be corrected through stable horizontal substructures.

All connections to other components or substrates are mandatory.

Elastic intermediate layers between panels and substructures, as well as between substructure parts, should allow for tolerances greater than ±0.5 millimeters, which must be avoided.

(7) Advantages of Non-Bearing Ventilated Curtain Walls:

Building decoration can be achieved through various designs and implementation modes.

Long-term preservation and appreciation of the building.

Precise cost estimation of the facade, long maintenance cycles, and low ongoing costs.

Installation possible under any weather conditions.

Can be installed on almost any surface, saving time with shorter brackets.