- Home

- Plastics

- Food Packaging

- TPX™ (Polymethyl Pentene)

TPX™ (Polymethyl Pentene)

Industry Categories

Functional

Product tags

Latest Products

Your most trustworthy partner

- Home

- Plastics

- Food Packaging

- TPX™ (Polymethyl Pentene)

Last updated:

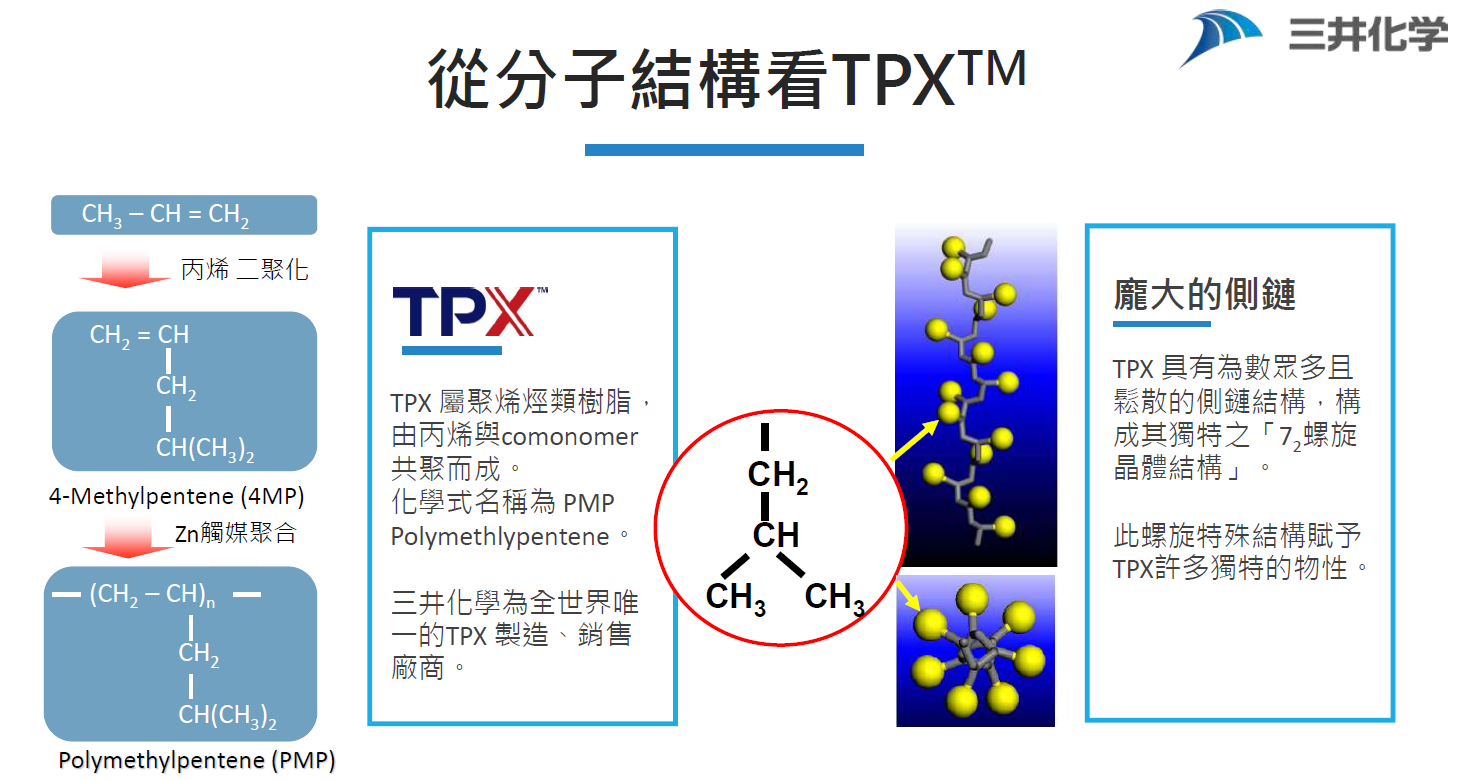

TPX™ is a polyolefin resin that is synthesized through Mitsui Chemical's unique resin polymerization technology. It is copolymerized with propylene and comonomers and has the chemical formula Polymethylpentene (PMP).

Mitsui Chemical is the only manufacturer and distributor of TPX™ in the world.

Examining TPX™ from its structure

Characteristics and Applications:

1.Heat Resistance

TPX™ has a Vicat Softening Temperature (VST) of approximately 145~170 ℃, making it a high-temperature resistant transparent crystalline plastic. Applications include heat-resistant microwave food containers, microwave preservation films, laboratory equipment, cosmetic containers, and medical devices.

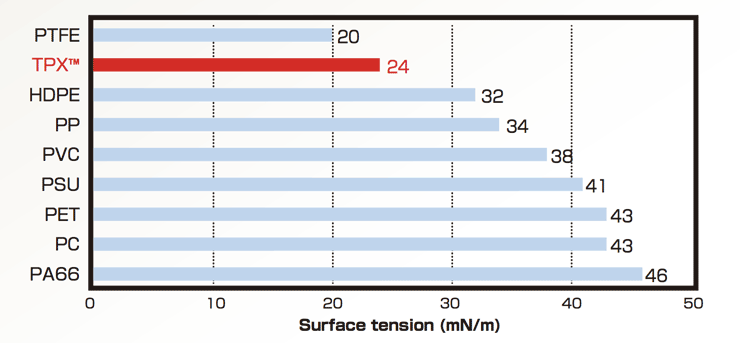

2.Release Properties

With a surface tension of 24 mN/m, TPX™ is second only to PTFE in terms of its ability to release from materials such as epoxy resins. Applications include anti-staining food containers, cutting boards, release films for FPC, release paper for synthetic leather, plastic modifications, and LED light strips.

3.Transparency

Despite being a crystalline resin, TPX™ exhibits high transparency comparable to glass, acrylic, and PC plastics. It has a light transmittance of 90% and Haze < 5%.

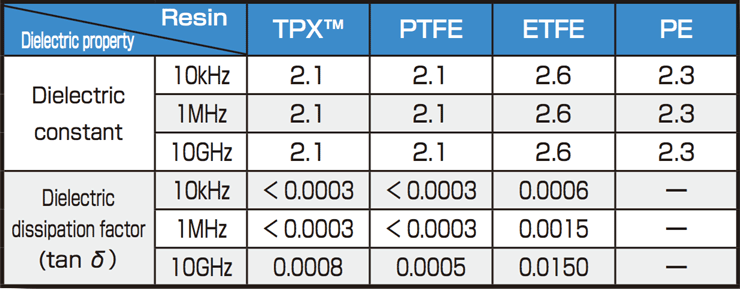

4.Low Dielectric Constant

Due to its non-polar structure, TPX™ boasts a low dielectric constant comparable to PTFE (10GHz, e=2.1), with minimal frequency-dependent effects on its dielectric properties.

5.Lightweight

Among thermoplastic resins, TPX™ is the lightest material with a density of 830 kg/m³. Its low density results in lightweight finished products compared to other plastics. It can also be used in combination with other plastics for lightweight effects. Applications include food containers, outer shell frames, and water sports goggles.

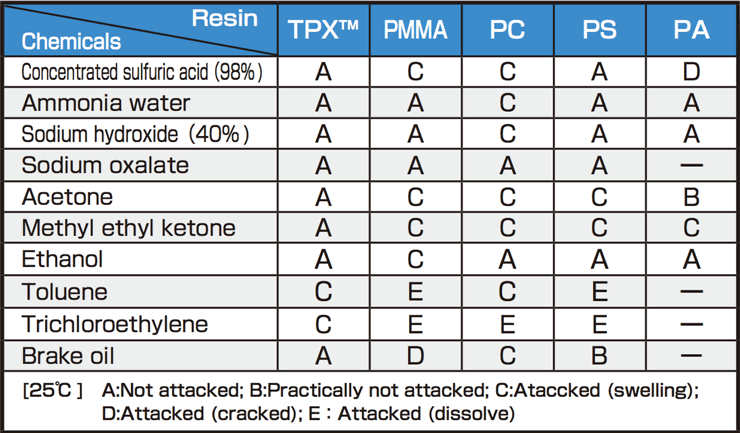

6.Chemical Resistance

Thanks to its stable C-C bonds, TPX™ offers superior chemical resistance compared to PC and acrylic materials. It demonstrates excellent durability against acids, bases, alcohols, and more. Applications include laboratory equipment, cosmetic containers, and medical devices.

7.Steam Resistance

Being a polyolefin, TPX™ has an extremely low water absorption rate, preventing changes in dimensions due to water absorption. It is also less susceptible to degradation from steam sterilization. Applications include pharmaceutical or laboratory equipment requiring steam sterilization, containers, and animal cages.